When you're designing parts that need to slide, align, or house wiring, slot milling is usually the best way to get there. It's the standard for creating keyways and precision grooves because it gives you a level of control that manual milling can't touch. We see this used constantly in automotive and industrial assemblies where alignment is everything. It's versatile enough to handle anything from soft plastics to hardened steel, provided you've got the right speeds and feeds dialed in.

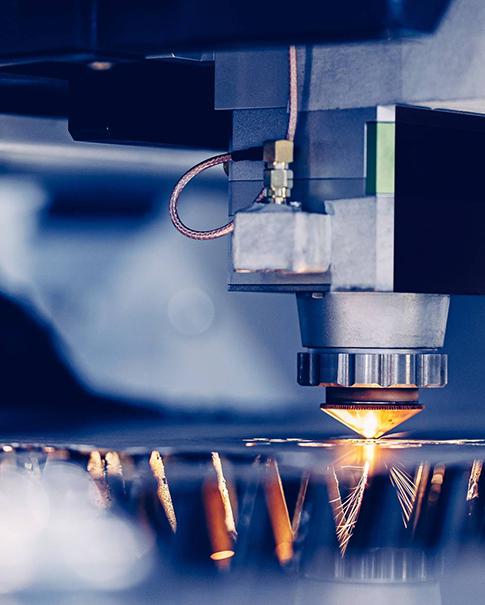

Slot milling is a subtractive machining technique where a rotating cutter plunges and moves along a programmed path to form an internal channel. Unlike CNC drilling, which only creates round holes, slot cutting shapes long cavities with precise depth, width, and direction. CNC control ensures the slot maintains geometry even through complex contours or hard materials.

Slot milling or slot cutting uses a milling cutter, usually an end mill, to remove material along a straight or curved line. The tool is fed laterally to form an elongated cavity (slot). CNC programs define the slot's dimensions, position, and structural features with exceptional accuracy, ensuring proper assembly fit or motion.

Many mechanical components are useless without proper guidance or alignment. Slots provide:

-Travel paths for moving components (like rails or sliders)

-Locking mechanisms such as keyways on rotating shafts

-Clearances for inserts, fasteners, retaining clips, and gaskets

-Weight reduction without sacrificing rigidity

-Routing channels for electronics, hoses, or lubrication

-Precise slot cutting avoids wobble, misalignment, or premature wear in assemblies.

Slot milling shows up in:

-Gearbox and motor housings

-Aerospace brackets and structural panels

-Automotive transmission and steering components

-Mold bases, dies, and tooling plates

-Robotics chassis and sensor mounts

-Custom brackets, jigs, and fixturing hardware

Whenever a part requires a controlled opening that positions or guides another part, slot cutting is typically the solution.

Keso is set up for precision from the first toolpath: rigid CNC mills, CAM-driven slot strategies, and finishing passes dialed to the micron. We apply proven CNC slot milling strategies to control tool load, slot accuracy, and surface finish in real production parts.