제목 : 혁신 제조 : CNC 가공의 전력

소개:

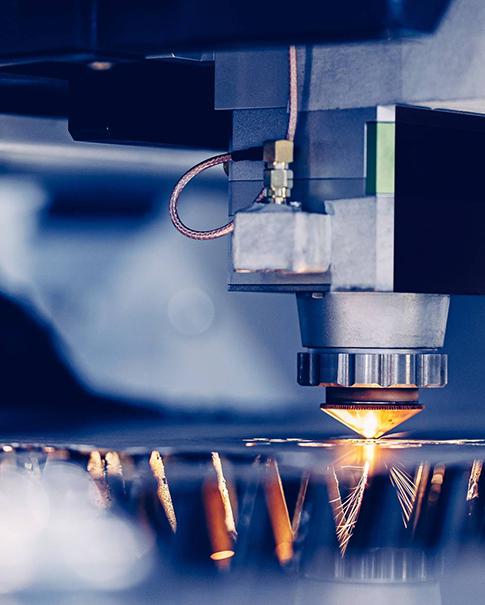

현대 제조의 세계에서 정밀도와 효율성은 성공을 결정하는 주요 요인입니다. 이 산업의 다양한 최첨단 기술 중에서 CNC (컴퓨터 수치 제어) 가공 부품이 생산되는 방식을 재정의 한 혁신적인 프로세스로 두드러집니다. 이 블로그에서는 CNC 가공의 복잡성, 응용 프로그램 및 제조의 미래를 형성하는 데 역할을 할 것입니다.

잠재력 잠금 해제 : CNC 가공 이해 :

CNC 가공은 컴퓨터 제어 기계를 사용하여 공작물에서 재료를 정확하게 제거하여 한때 달성 할 수없는 것으로 간주되었던 복잡하고 정확한 모양을 만듭니다. CNC 가공은 수동 개입에 크게 의존하는 전통적인 가공 방법과 달리 이전에 상상할 수없는 자동화 및 정밀도를 제공합니다. 이 과정에는 컴퓨터 프로그램, 일반적으로 CAD (컴퓨터 보조 디자인) CNC 머신에 파일을 파일 한 다음 원료를 원하는 형태로 만들기위한 지침을 실행합니다.

CNC 가공의 장점 :

1. 정밀성과 정확성 : CNC 기계는 완벽한 정확도로 작업을 반복하여 일관된 결과를 제공 할 수 있습니다. 이 수준의 정밀도는 완성 된 부품이 더 큰 어셈블리에 완벽하게 맞도록하여 재 작업의 필요성을 줄이고 오류를 최소화합니다.

2. 유연성 : CNC 가공은 금속, 플라스틱 및 복합재를 포함한 다양한 재료를 처리 할 수 있습니다. 이 다양성을 통해 제조업체는 항공 우주, 자동차, 전자 제품 및 의료 기기 제조와 같은 다양한 산업을위한 부품을 만들 수 있습니다.

3. 효율성 : 프로세스를 자동화 할 수있는 능력으로 CNC 가공은 생산에 필요한 시간을 크게 줄입니다. 이 가속화 된 제조 공정은 전반적인 생산성을 향상시키고 고품질 표준을 유지하면서 까다로운 마감일을 충족시키는 데 도움이됩니다.

4. 복잡한 형상 : 복잡한 디자인, 타이트한 공차 또는 복잡한 모양이든 CNC 가공은 전통적인 방법이 도전적인 부품을 생산하는 데 탁월합니다. 이를 통해 제조업체는 고도로 복잡하고 맞춤형 구성 요소를 만들어 경계를 넓히고 혁신 할 수 있습니다.

CNC 가공의 응용 프로그램 :

1. 항공 우주 산업 : CNC 가공은 항공 우주 제조에 중요한 역할을하며 터빈 블레이드, 랜딩 기어 부품 및 항공기 구조와 같은 구성 요소를 만듭니다. CNC 가공의 정확하고 신뢰할 수있는 특성은 이러한 중요한 부품의 무결성과 안전성을 보장합니다.

2. 자동차 산업 : 엔진 부품에서 복잡한 내부 부품에 이르기까지 CNC 가공은 자동차 부문에 필수적입니다. 이를 통해 제조업체는 연료 효율, 성능 및 전반적인 차량 안전을 향상시키는 가벼운 내구성 부품을 생산할 수 있습니다.

3. 전자 산업 : CNC 가공은 회로 보드, 커넥터 및 인클로저와 같은 전자 부품 생산에 사용됩니다. CNC 가공의 정확도는 구성 요소가 원활하게 함께 맞도록하여 전자 장치의 기능과 신뢰성을 향상시킵니다.

4. 의료 산업 : CNC 가공은 복잡하고 맞춤화 된 부품이 필수적인 의료 분야에서 필수적입니다. 그것은 개별 환자 요구에 맞는 정확하고 신뢰할 수 있으며 맞춤형 수술기구, 보철 및 의료 기기 구성 요소를 생산할 수 있습니다.

CNC 가공으로 미래 수용 :

산업이 계속 발전함에 따라 CNC 가공은 최첨단 제조 기술의 최전선에 남아 있습니다. 속도와 정확도로 복잡하고 고품질 부품을 생산하는 능력은 다양한 부문에서 필수 도구가됩니다. 소프트웨어, 자동화 및 툴링의 발전으로 CNC 가공은 제품의 미래를 형성하여 제조업을 더욱 혁신하도록 설정되어 있습니다.

결론:

CNC 가공이 혁명을 일으켰습니다 제조 산업효율성과 정확성을 갖춘 복잡하고 정확하며 맞춤형 부품을 생성 할 수 있습니다. 응용 프로그램은 항공 우주, 자동차, 전자 제품 및 의료 산업을 포함한 여러 부문에 걸쳐 있습니다. 우리가 미래를 수용함에 따라, CNC 가공은 현대 제조의 세계를 형성하는 데 계속 지배적 인 역할을합니다.

태그 :