CNC 기계는 수용 가능한 부품의 크기와 형태에 물리적인 한계가 있습니다. 기계의 작업 범위는 가공 가능한 부품의 최대 치수를 결정합니다. 또한, 깊은 포켓이나 좁은 채널과 같은 복잡한 형상은 정밀 가공이 어렵거나 불가능할 수 있습니다.

따라서 먼저 제공된 데이터를 기반으로 프로젝트 제작이 가능한지 확인해 주세요. 더 궁금한 점이 있으시면 언제든지 고객센터로 문의해 주세요. 최대한 빨리 답변해 드리겠습니다.

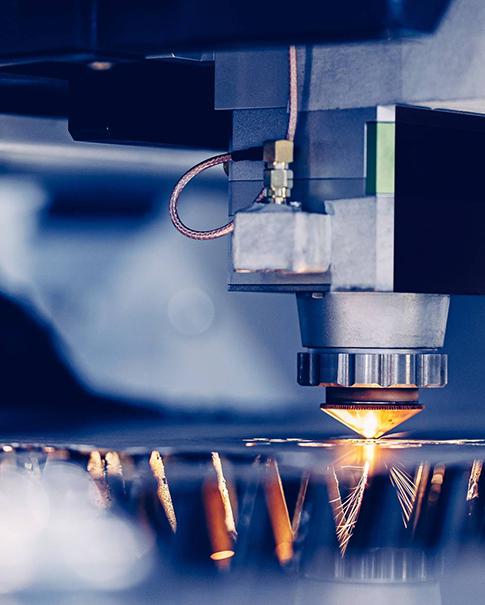

CNC 가공 다음을 포함한 광범위한 재료와 호환됩니다. 금속, 플라스틱, 구리그러나 재료마다 가공성이 다릅니다. 경화강이나 내열 합금과 같은 일부 재료는 특수 공구와 더 느린 절삭 속도가 필요할 수 있는 반면, 연성 플라스틱과 같은 다른 재료는 가공 중 변형되거나 녹기 쉽습니다.

CNC 가공은 정교한 디테일을 구현할 수 있지만, 안정적으로 구현 가능한 최소 형상 크기와 벽 두께에는 제약이 있습니다. 얇은 벽은 가공 중 진동이나 변형에 취약하여 치수 부정확도가 발생할 수 있습니다. 마찬가지로, 매우 작은 형상은 절삭 공구와 기계 분해능의 한계로 인해 정밀 가공이 어려울 수 있습니다.

CNC 기계는 다양한 절삭 공구를 사용하여 가공물에서 재료를 제거합니다. 필요한 모든 부분에 도달할 수 있도록 공구 접근성을 충분히 확보하도록 설계되어야 합니다. 돌출부나 접근하기 어려운 부분에는 특수 공구나 여러 가지 셋업이 필요할 수 있으며, 이는 가공의 복잡성과 비용을 증가시킵니다.

CNC 기계는 일반적으로 위에서 공작물에 접근하기 때문에 언더컷과 오버행(수직축을 넘어 연장되는 형상) 가공이 어려울 수 있습니다. 이러한 한계를 해결하기 위해 추가 설정이나 5축 가공과 같은 특수 가공 기술이 필요할 수 있습니다. Keso는 3, 4, 그리고 5축 CNC 장비.

CNC 가공은 정밀한 공차와 우수한 표면 조도를 얻을 수 있습니다. 그러나 매우 정밀한 공차나 까다로운 표면 조도를 구현하는 경우 가공 공정의 복잡성과 비용이 증가할 수 있습니다. 설계의 특정 요구 사항을 고려하고 CNC 가공 업체와 협의하여 실현 가능성을 확인하는 것이 중요합니다.